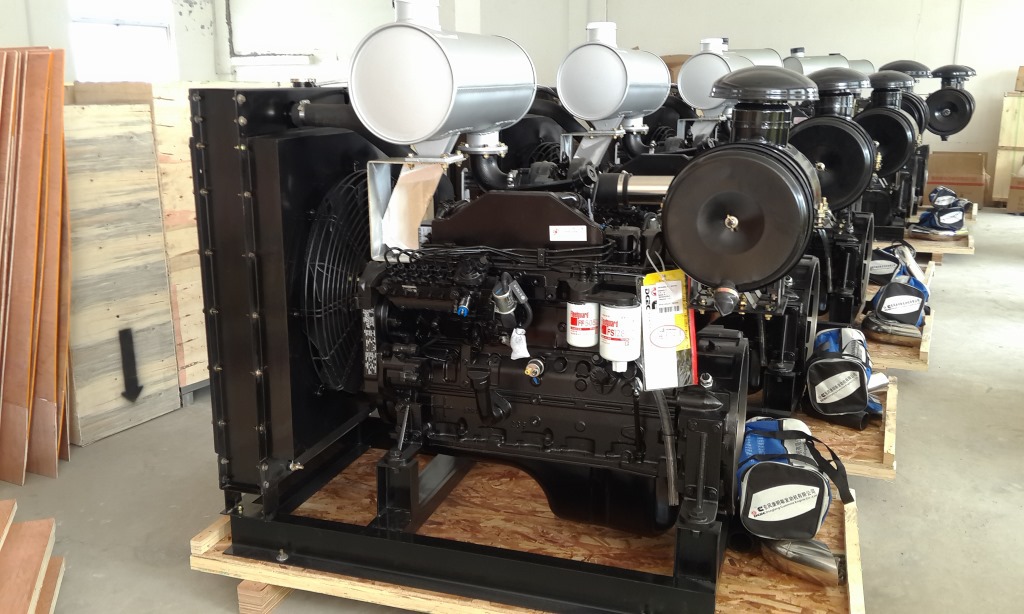

DCEC 6BTAA5.9-C160 Industrial Application Engine

| Engine Model | 6BTAA5.9-C160 |

| Rated Power / Speed: | 160 HP @ 2200 RPM |

| Peak Torque: | 670 N.m @ 1500 RPM |

| Type | 6 Cylinders, in Line |

| Fuel System | Weifu PW2000 Pump RSV Mechanical Governor |

| Aspiration | Turbocharged & Air-Air Intercooler |

| Displacement | 5.9 L |

| Bore * Stroke | 102 mm * 120 mm |

| Packing Size (L * W * H) | 778 mm * 634 mm * 912 mm |

| Lead Time: | 5-15 Working Days |

General Infomation of DCEC 6BTAA5.9-C160 Industrial Engine

| General Infomation of DCEC 6BTAA5.9-C160 Industrial Engine | |

| Engine Model | 6BTAA5.9-C160 |

| Rated Power | 160 HP @ 2200 RPM |

| Curve&Datasheet | FR92792 |

| Compression Ratio | 17.3 : 1 |

| No. of Cylinders | 6 Cylinders, in Line |

| Fuel System | Weifu PW2000 Pump / RSV Mechanical Governor |

| Aspiration | Turbocharged & Air-Air Intercooler |

| CPL Code Revision | 3106 |

| Emission Standard | Euro Stage II |

| Peak Torque | 670 N.m @ 1500 RPM |

| Displacement | 5.9 L |

| Bore * Stroke | 102 mm * 120 mm |

| Governor Regulation | 0.08 |

| Wet Weight | 413 kg |

| Configuration | D403042CX02 |

| Packing Size(L * W * H) | 1026 mm * 699 mm * 912 mm |

| Installation Data of DCEC 6BTAA5.9-C160 Industrial Engine | |

| Maximum Overspeed Performance | 4200 RPM |

| Moment of Inertia of Rotating Components (No Flywheel) | 0.25 kg·m² |

| Center of Gravity From Front Face of Block | 328 mm |

| Center of Gravity Above Crankshaft Centerline | 155 mm |

| Maximum (Static) Bending Moment At Front Support Mounting Surface | 435 N.m |

| Maximum (Static) Bending Moment At Side Pad Mounting Surface | 141 N.m |

| Maximum (Static) Bending Moment at Rear Face of Block | 1356 N.m |

| Instantaneous Inertia of the Finished Engine- Double Shaft | 14.8 kg·m² |

| Instantaneous Inertia of the Finished Engine- Pitch Axis | 36.9 kg·m² |

| Instantaneous Inertia of the Finished Engine- Partial Rotation | 31.9 kg·m² |

| Crankshaft Thrust Bearing Load Limit, Instantaneous Maximum | 3781 N |

| Crankshaft Thrust Bearing Load Limit, Continuous Maximum | 1780 N |

Performance Data of DCEC 6BTAA5.9-C160 Industrial Engine

| Engine Performance Data Rated Power of DCEC 6BTAA5.9-C160 Industrial Engine | |||||

| Rated Power | Torque Peak | Rated Power | Torque Peak | ||

| Engine Speed | 2200 RPM | 1500 RPM | Intake Air Flow | 190 L/s | 120 l / s |

| Gross Power Output | 118 kW | 105 kW | Exhaust Gas Flow | 425 L/s | 290 l / s |

| Torque | 512 N.m | 670 N.m | Exhaust Gas Temperature | 390 °C | 440 °C |

| Friction Horsepower | 25 kW | 13 kW | Heat Rejection to Ambient | 13.2 kW | 9.3 kW |

| Intake Manifold Pressure | 155 kPa | 122 kPa | Heat Rejection to Coolant | 64 kW | 57.6 kW |

| Turbo Comp. Outlet Pressure | 168 kPa | 125 kPa | Steady State Smoke | 1 FSN | 1.2 FSN |

| Turbo Comp. Outlet Temperature | 150 °C | 126 °C | |||

Advantages of DCEC 6BTAA5.9-C160 Industrial Engine

Integrated Design & Reduced Complexity:

Cylinder Block/Head Integration: A unified design minimizes parts by 40% compared to conventional engines, reducing assembly complexity and potential failure points.

Leak Prevention: Eliminates water/oil leakage risks, enhancing durability in harsh conditions and lowering maintenance needs.

- Robust Construction & Materials:

Forged Steel Components: Camshaft and crankshaft made from forged steel ensure high strength, fatigue resistance, and longevity under heavy loads.

High-Strength Block: Reinforced casting integrates multiple parts, boosting rigidity, pressure resistance, and structural reliability.

- Precision Sealing & Oil Control:

Platform Mesh Honing: Cylinder bore surface treatment optimizes geometric integrity, preventing oil leakage.

Advanced Sealing Tech: New piston rings and crimped gaskets further reduce oil consumption and leakage risks.

- In-House Engine Control Systems:

DCEC-Developed Electronics: Five core systems (e.g., fuel injection, emission control) are designed and validated globally, ensuring adaptability and reliability across diverse environments.

Proven Performance: Extensive real-world testing underpins exceptional fuel economy and operational consistency.

- Overall Benefits:

Enhanced Reliability: Fewer parts and robust construction slash failure rates.

Long Service Life: Durable materials and sealing tech extend operational lifespan.

Economic Efficiency: Optimized design and electronics reduce fuel/oil waste, lowering total cost of ownership.

This engine is engineered for demanding applications, prioritizing longevity, efficiency, and reliability through innovative design and rigorous testing.chieves a balance of power, reliability, eco-compliance, and cost-effectiveness. Ideal for non-road applications such as engineering machinery and agricultural equipment, it delivers an efficient, durable, and user-friendly power solution.