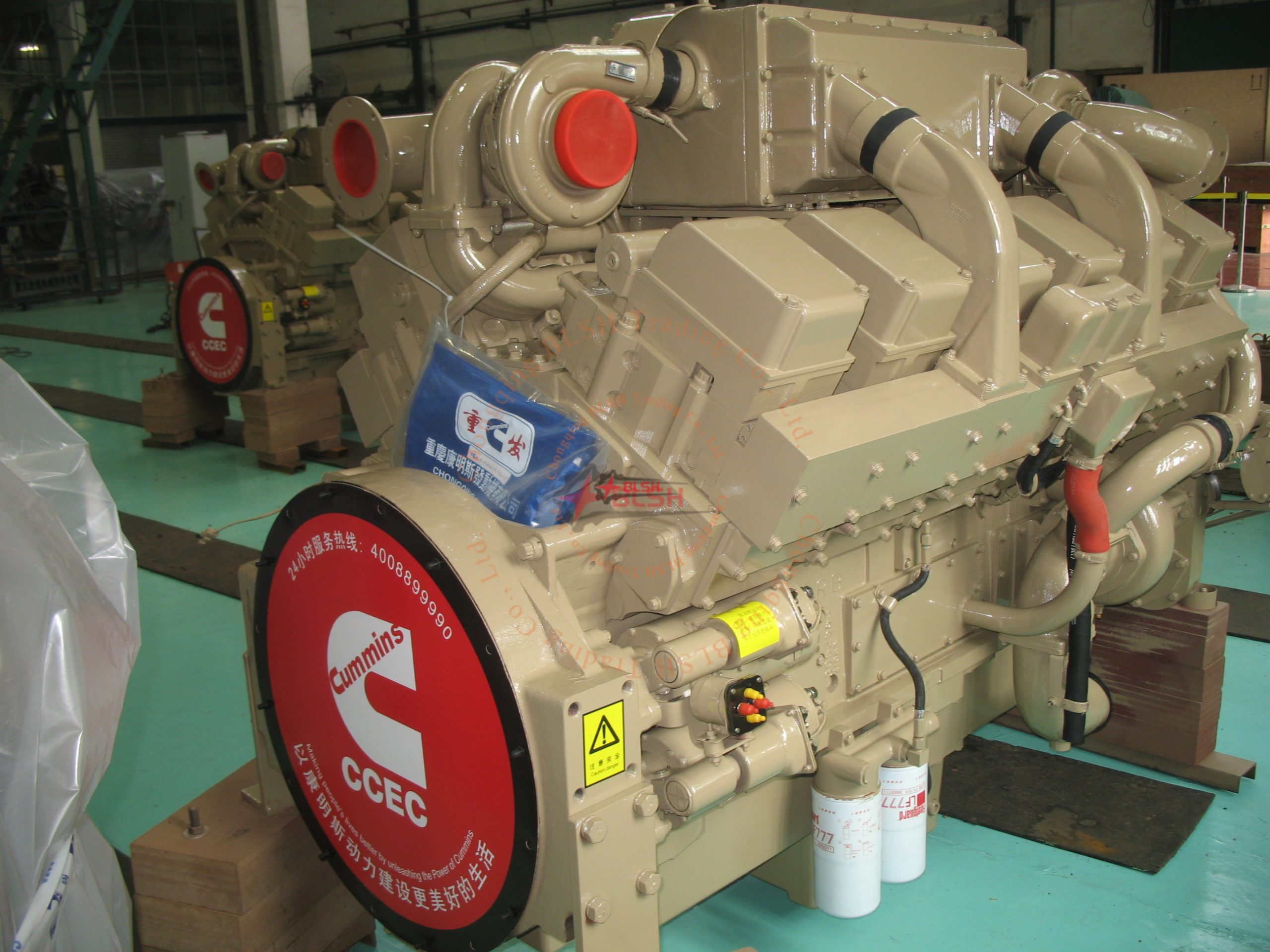

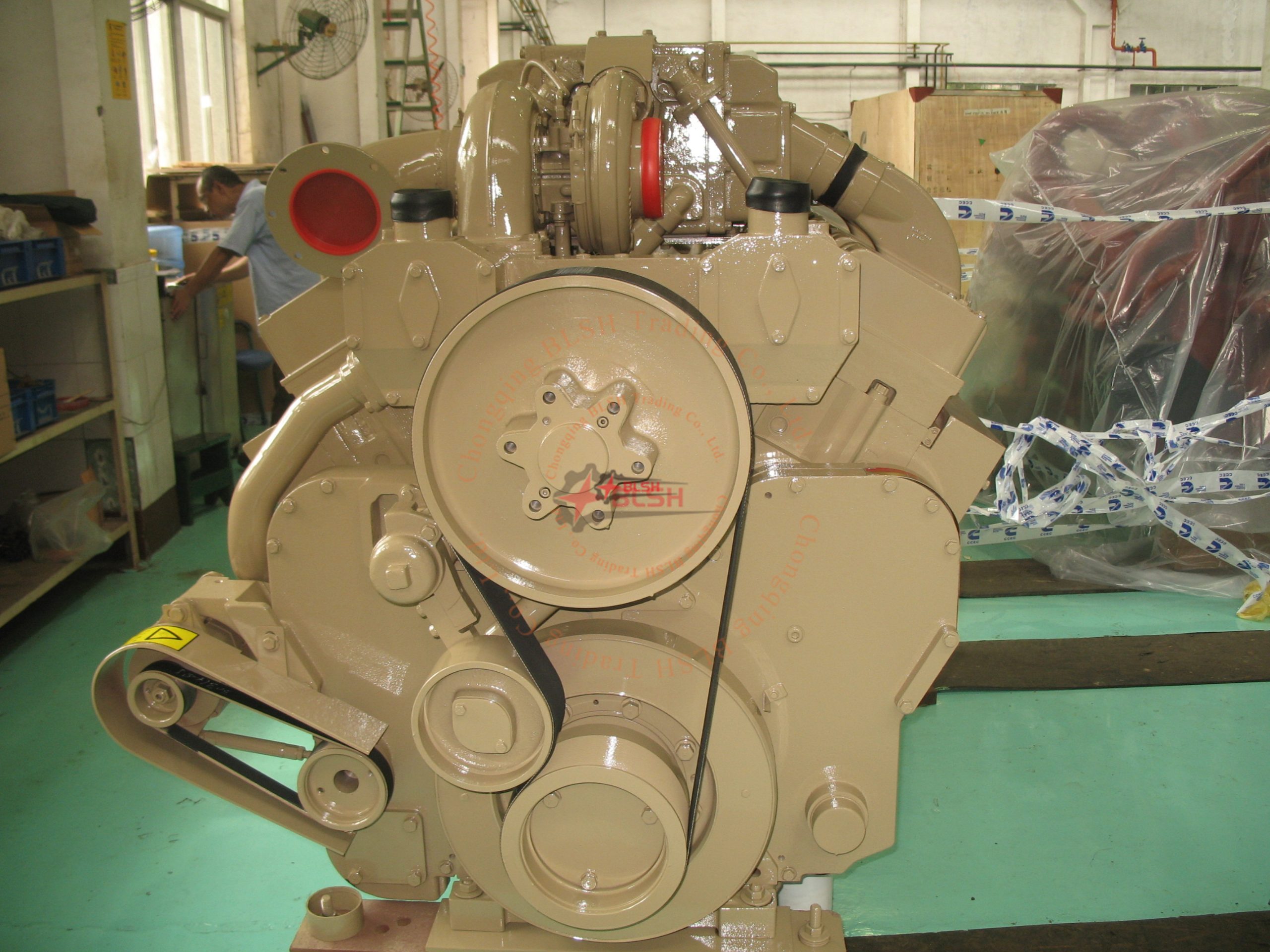

CCEC KTA38-G5 Generator Engines

| Engine Model | KTA38-G5 |

| Standby Power | 1300 HP (970 kW) @ 1500 RPM |

| Prime Power | 1180 HP (881 kW) @ 1500 RPM |

| Compression Ratio | 13.9 : 1 |

| Type | 4 Cycle; 12 Cylinder |

| Fuel System | PT-STC |

| Aspiration | Turbocharged & Aftercooled |

| Emission Standard | Euro II |

| Displacement | 38 L |

| Bore * Stroke | 159 mm * 159 mm |

| Packing Size (L * W * H) | 2341 mm * 1360 mm * 1653 mm |

General Infomation of CCEC KTA38-G5 Generator Engines

| General Infomation of CCEC KTA38-G5 Generator Engine | |||

| Engine Model | KTA38-G5 | Configuration | D233031DX02 |

| Performance Curve | FR – 6140 | CPL No. | 1543 |

| Type | 4 – Cycle; 60° Vee; 12 – Cylinder Diesel | Aspiration | Turbocharged & Aftercooled Intercooler |

| Bore * Stroke | 159 mm * 159 mm / 6.25 in * 6.25 in | Displacement | 2300 in3 / 37.8 L |

| Compression Ratio | 13.9 : 1 | Stand_By Power | 1300 HP (970 kW) @ 1500 RPM |

| Prime Power | 1180 HP (881 kW) @ 1500 RPM | Fuel System | CMI PT |

| Installation Data of CCEC KTA38-G5 Generator Drive Engine | |||

| Wet Weight – Fan to Flywheel Engine | 10002 lb / 4536 kg | ||

| Wet Weight – Heat Exchanger Cooled Engine | 10602 lb / 4808 kg | ||

| Moment of Inertia of Rotating Components – with FW 6001 Flywheel | 248 lbm.ft2 / 10.4 kg.m2 | ||

| Center of Gravity from Rear Face of Flywheel Housing (FH 6024) | 38.6 in / 980 mm | ||

| Maximum Static Loading at Rear Main Bearing | 2000 lb / 908 kg | ||

| Dry Weight – Fan to Flywheel Engine | 9482 lb / 4300 kg | ||

| Dry Weight – Heat Exchanger Cooled Engine | 9923 lb / 4500 kg | ||

| Maximum Bending Moment at Rear Face of Block | 4500 lb.ft / 6100 N.m | ||

| Moment of Inertia of Rotating Components – with FW 6011 Flywheel | 493 lbm.ft2 / 20.8 kg.m2 | ||

| Center of Gravity Above Crankshaft Centerline | 11.0 in / 279 mm | ||

Engine Performance Data CCEC KTA38-G5 Generator Engines

| Performance Data of CCEC KTA38-G5 Generator Engine | |||||

| Stanby Power | Prime Power | Stanby Power | Prime Power | ||

| Engine Speed | 1500 RPM | 1500 RPM | Engine Idle Speed | 725 – 775 RPM | 725 – 775 RPM |

| Gross Engine Power Output | 1300 HP / 970 kW | 1180 HP / 880 kW | Brake Mean Effective Pressure | 298 PSI / 2055 kPa | 271 PSI / 1868 kPa |

| Piston Speed | 1562 ft/min / 7.9 m/s | 1562 ft/min / 7.9 m/s | Friction Horsepower | 115 HP / 86 kW | 115 HP / 86 kW |

| Intake Air Flow | 2570 cfm / 1213 L/s | 2415 cfm / 1140 L/s | Exhaust Gas Temperature | 955 °F / 513 °C | 930 °F / 499 °C |

| Exhaust Gas Flow | 7005 cfm / 3306 L/s | 6465 cfm / 3051 L/s | Radiated Heat to Ambient | 7820 HP / 137 min/kW | 7135 HP / 125 min/kW |

| Heat Rejection to Coolant | 33800 HP / 594 min/kW | 30680 HP / 539 min/kW | Heat Rejection to Exhaust | 33575 HP / 590 min/kW | 30990 HP / 544 min/kW |

| Engine Water Flow at Stated Friction Head External to Engine – 4 psi Friction Head | 310 US gpm / 19.6 L/s | 310 US gpm / 19.6 L/s | Engine Water Flow at Stated Friction Head External to Engine – Maximum Friction Head | 280 US gpm / 17.7 L/s | 280 US gpm / 17.7 L/s |

| Air to Fuel Ratio (air : fuel) | 26.5 : 1 | 26.1 : 1 | |||

System Technical Data of CCEC KTA38-G5 Generator Engines

| System Technical Data of CCEC KTA38-G5 Generator Engine | ||

| Exhaust System | Maximum Back Pressure | 3 in Hg / 76 mm Hg |

| Air Induction System | Maximum Intake Air Restriction – with Dirty Filter Element | 25 in H2O / 635 mm H2O |

| Maximum Intake Air Restriction – with Normal Duty Air Cleaner and Clean Filter Element | 10 in H2O / 254 mm H2O | |

| Maximum Intake Air Restriction – with Heavy Duty Air Cleaner and Clean Filter Element | 15 in H2O / 381 mm H2O | |

| Coolig System | Coolant Capacity – Engine Only | 32.7 US gal / 124 liter |

| Coolant Capacity – with HX 6076 Heat Exchanger | 52.7 US gal / 199 liter | |

| Maximum Coolant Friction Head External to Engine – 1500 RPM | 7 PSI / 48 kPa | |

| Maximum Static Head of Coolant Above Engine Crank Centerline | 60 ft / 18.3 m | |

| Standard Thermostat (Modulating) Range | 180 – 200 °F / 82 – 93 °C | |

| Minimum Pressure Cap | 10 PSI / 69 kPa | |

| Maximum Top Tank Temperature for Standby / Prime Power | 220 / 212 °F / 104 / 100 °C | |

| Minimum Raw Water Flow @ 90 °F to HX 6076 Heat Exchanger | 108 US gpm / 409 liter/min | |

| Maximum Raw Water Inlet Pressure at HX 6076 Heat Exchanger | 50 PSI / 345 kPa | |

| Lubrication System | Oil Pressure @ Idle Speed | 20 PSI / 138 kPa |

| Oil Pressure @ Governed Speed | 45 – 65 PSI / 310 – 448 kPa | |

| Maximum Oil Temperature | 250 °F / 121 °C | |

| Oil Capacity with OP 6023 Oil Pan : High – Low | 30 – 23 US gal / 114 – 87 liter | |

| Total System Capacity (Including Bypass Filter) | 35.7 US gal / 135 liter | |

| Angularity of OP 6023 Oil Pan – Front Down | 30 ° | |

| Angularity of OP 6023 Oil Pan – Front Up | 30 ° | |

| Angularity of OP 6023 Oil Pan – Side to Side | 30 ° | |

| Fuel System | Type Injection System | Direct Injection PT |

| Maximum Restriction at PT Fuel Injection Pump – with Clean Fuel Filter | 4 in Hg / 102 mm Hg | |

| Maximum Restriction at PT Fuel Injection Pump – with Dirty Fuel Filter | 8 in Hg / 203 mm Hg | |

| Maximum Allowable Head on Injector Return Line (Consisting of Friction Head and Static Head) | 6.5 in Hg / 165 mm Hg | |

| Maximum Fuel Flow to Injection Pump | 113 US gph / 428 liter/hr | |

| Electrical System | Cranking Motor (Heavy Duty, Positive Engagement) | 24 V |

| Battery Charging System, Negative Ground | 35 ampere | |

| Maximum Allowable Resistance of Cranking Circuit | 0.002 ohm | |

| Minimum Recommended Battery Capacity – Cold Soak @ 50 °F (10 °C) and Above | 12000 °F CCA | |

| Minimum Recommended Battery Capacity – Cold Soak @ 32 °F to 50 °F (0 °C to 10 °C) | 12800 °F CCA | |

| Minimum Recommended Battery Capacity – Cold Soak @ 0 °F to 32 °F (-18 °C to 0 °C) | 18000 °F CCA | |

CCEC KTA38-G5 Generator Engines Product Advantages

Durable and Rugged

The cylinder block and cylinder head feature high-strength integrated design, reducing failure rates and ensuring long-lasting durability. Renowned for exceptional reputation.

High Reliability

Equipped with Cummins’ advanced PT fuel system, offering unique overspeed protection and low-pressure fuel supply. Minimal piping reduces failure rates. Derived from superior overall design, delivering outstanding reliability.

Superior Performance

- High-efficiency Cummins exhaust turbocharger ensures optimal air intake, enhancing engine efficiency.

- Pressure pulse exhaust manifold fully utilizes exhaust energy, further improving combustion and increasing low-load efficiency while reducing specific fuel consumption.

- High torque output, powerful performance, fast transient response, and exceptional torque reserve.

Easy Maintenance

Six-cylinder single-head integrated design with modularized structure ensures compactness. Components are detachable and highly reusable.