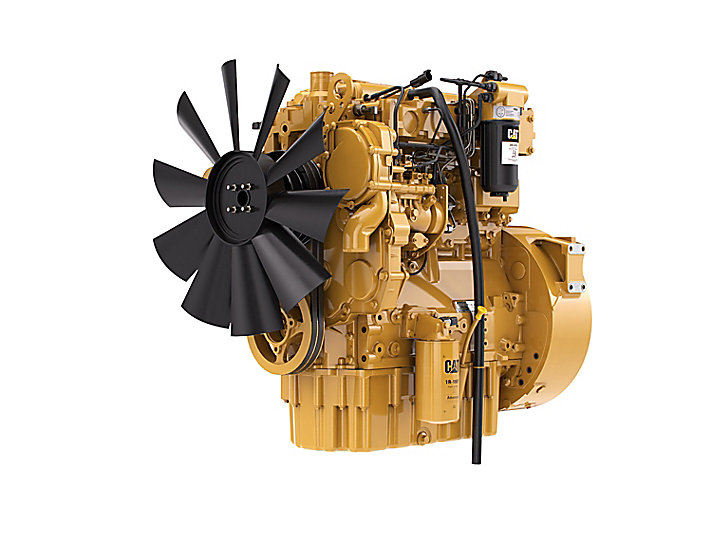

Caterpillar C4.4 150 kW diesel engine

| Engine Model | C4.4 150 kW diesel engine |

| Maximum power: | 150 kW |

| Peak Torque: | 825 Nm @ 1400 rpm |

| Type | 4 Cylinders, in Line |

| Rated speed | 2000 to 2200 rpm |

| Minimum power | 82 kW |

| Emissions | China Non-road National IV |

| Bore * Stroke | 105 mm * 127 mm |

| Packing Size (L * W * H) | 822mm * 748mm * 897mm |

| Lead Time: | 5-15 Working Days |

General Infomation of C4.4 150 kW Diesel Engine

| General Infomation of C4.4 150 kW Diesel Engine | |

| Engine Model | C4.4 150 kW diesel engine |

| Maximum Power | 129.4 kW |

| Maximum Torque | 750 Nm @ 1400 rpm |

| Rated Speed | 2000 to 2200 rpm |

| Minimum Power | 82 kW |

| Emissions | China Nonroad National IV Standard |

| Engine Configuration | Inline 4-cylinder |

| Bore | 105 mm |

| Stroke | 127 mm |

| Displacement | 4.4 |

| Compression Ratio | 16.5:1 |

| Intake Method | CoTurbocharged, Aftercooled (TA) |

| Combustion System | Direct Injection |

| Rotation (from Flywheel End) | Counterclockwise |

| Aftertreatment Devices | DOC+DPF or DOC+DPF+SCR |

| Length | 630 mm |

| Width | 748 mm |

| Height | 897 mm |

| Dry weight – basic operating engine, without optional accessories | 535 kg |

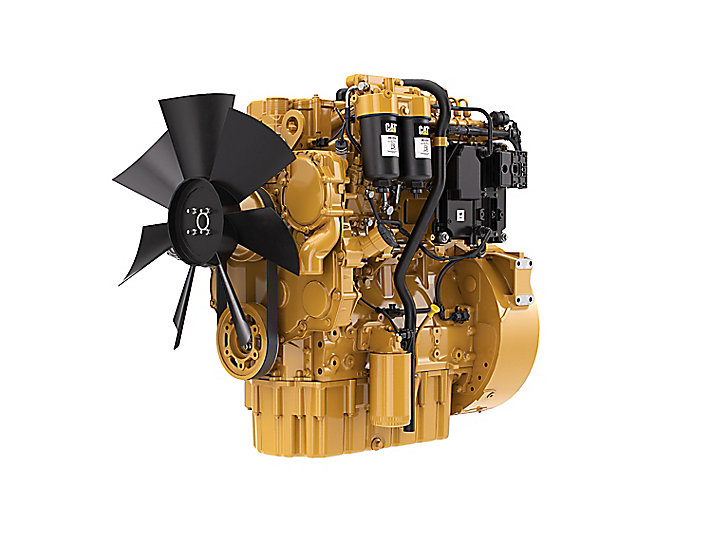

The C4.4 150 kW Diesel Engine Standard Equipment

C4.4 150 kW Diesel Engine

Air Intake System

Standard Air Filter

Control System

Fully electronic control system with waterproof connectors and wiring bushings to withstand harsh off-road environments

Flexible, configurable software and widely supported SAE J1939 CAN bus enable high machine integration

Cooling System

A top tank temperature of 108°C (226°F) is standard, minimizing the size of the cooling package

50:50 water/ethylene glycol mixture

Flywheel and flywheel housing

Installation of standard SAE3 configurations

Fuel System

Electronic high-pressure common rail

Innovative filter design ensures optimal engine protection

Lubrication System

Multiple oil sump options for different applications

Power Take-off

SAE A and SAE B flanges on the left. Additional SAE A flange on the left. Engine power can also be drawn from the front of the engine in certain applications. A factory-installed compressor is also available. Universal

With or without balancer

Paint: Caterpillar Yellow, optional colors available upon request

China Nonroad IV Standard Aftertreatment/Clean Emission Control Equipment

Clean Emission Module (CEM) consisting of a Diesel Particulate Filter (DPF) and a Diesel Oxidation Catalyst (DOC)

Selective Catalytic Reduction (SCR)

3″ hose connection with straight, 45°, and 90° options for increased flexibility